Our Manufacturing Process

At Harisharan we believe in giving the highest quality marble to our clients and so we control all aspects of the process from Mining, to Manufacturing to Supplying marble to India & globally.

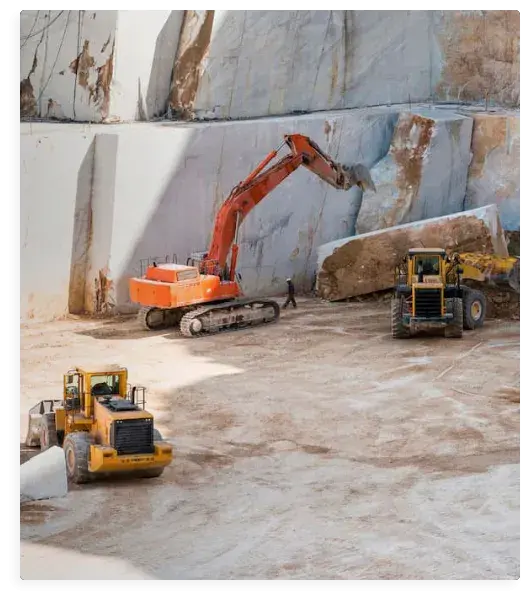

1 Receipt of raw marble blocks from mines

The raw marble blocks received from mines are unloaded in the gantry yard with the help of Gantry Cranes. These blocks are weighs in tonnes constitutes of metamorphic rocks.

2 Dressing of Marble Blocks

As per the requirement of length and width of slab,decision being made. dressing machine operator dresses the marble block from all the sides for removal of natural defects and make prefect.

3 Block Reinforcement

After dressing of slab, there is a process that cut the rough Blocks into slabs in Gangsaw. to do this, it is reinforced with fibre glass net and a semi-solid reinforcement product. Then it is pasted on the exterior of the blocks. Four sides of the blocks are treated, and the block then cures for 24 hours. On average, it takes 30 to 60 minutes to treat an entire block, depending on its size. This particular process to done to avoid breakage of slab during sawing and further other process.

4 Sawing Process

The dressed and reinforced blocks are shifted to the Gangsaw trolley as per the size of the Gangsaw machine. The block is fixed on the trolley with a wooden wedge and a mixture of Plaster of Paris and wood wool at the suitable angle.

5 Net-reinforcement of marble slabs

Glass fibre net is applied on back face of the marble slabs to strengthen the slabs which are fragile and to enable safe handling and transportation. The glass fibre net is peeled off before fixing by the customer.

6 Grinding Process & Resin Treatment

Rough Grinding of Marble slab - After the 1st stage of epoxy filling the marble slabs are processed in the Grinding Machine and then these processed slabs are shifted to the RESIN line for final epoxy resin treatment.Then, Resin Treatment is performed with the help of Resin Line “RES 90 LUX”. This plant has a length of 64 meters and width of 10 meters. The capacity of the machine is 30 slabs per hour. The new Resin Treatment Plant model "RES 120 LUX" has a capacity of 40 slabs per hour. This new plant is being installed in a 126 meter long and 32 meter wide building shed. This machine carries out filling of cracks present in marble slabs with a mixture of resin and hardener in a particular ratio. Excess resin on the surface is lapped off to enhance the strength and surface finish of the slab.